| The use of ceramics can be traced back to the

early history of mankind. Reliable archaeological research

has shown that the first ceramic figures were formed

from malleable ceramic material and hardened by fire

more than 24,000 years ago. Almost 10,000 years later,

as our ancestors developed settled communities, tiles

were first manufactured in Mesopotamia and India. The

first useful vessels were then produced in Central Europe

between 7,000 and 8,000 years ago.

Until the end of the Middle Ages, the

smelting and process furnaces of the early metal industry

were constructed using natural sandstone bonded with

kaolinite or siliceous material. The development of

synthetic refractory materials (Agricola, Freiberg around

1550) was one of the foundation stones of the industrial

revolution, and created the necessary conditions for

melting metals and glass on an industrial scale, and

for the manufacture of coke, cement and ceramics.

The ceramics industry was an important

partner to the chemical industry. Acid-resistant stoneware

and porcelain were for a long time the most important

materials available for corrosion protection. Nowadays

they have largely been replaced by acid-resistant steels

and enamels, but also by ceramics based on oxides, nitrides

and carbides.

Beginning in the second half of the

19th century, electro-ceramics provided the momentum

for industrial development. During this time, basic

solutions for electrical insulation based on porcelain

were developed.

It is difficult to determine the precise

beginning of modern, high-performance ceramic materials.

Until the turn of the 20th century, the development

of ceramic materials had a primarily empirical character.

Scientific methods were first applied to ceramics in

the course of the 20th century.

The development of manufacturing technologies

using quartz-enriched porcelain achieved bending strengths

of more than 100 MPa for the first time. It was only

in the 1960s, with the systematic development of alumina

porcelain, that marked increases in strength, especially

in large insulators for voltages over 220 kV, resulted

in considerable weight reductions.

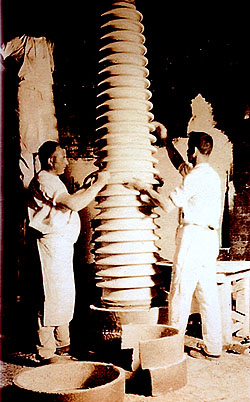

Figure 1: Manufacture

of insulators around 1920.

The growth of broadcast radio in the 1920s led to the

need for special ceramic insulation materials that did

not heat up under the influence of high-frequency electromagnetic

fields. This led to the development of steatite and

forsterite, both of which are still in use today. Research

on oxide magnetic materials began in the 1940s (hard

ferrites, soft ferrites). At this time, capacitor materials

based on titanium oxide were also developed, and research

began on the ferroelectric and piezoelectric properties

of perovskite (BaTiO3). This made a wide palette of

materials available – some even with semiconducting

properties – for sensors, frequency selective

components (filters) and capacitors with high storage

capacity. Theoretical considerations are derived from

basic research by Heisenberg, Dirac, Heitler, Londas,

Hartre and Fock, among others.

A further important milestone was the

introduction of sparkplugs made of sintered alumina

(Siemens, 1929). The development of micro-electronics

increased the demand for aluminium oxide materials,

for example, as a material for substrates and housings.

An important property of this material, in addition

to high electrical resistance, low dielectric losses,

high thermal conductivity, high mechanical strength

and thermal shock resistance, is the vacuum tightness

offered by these new types of material.

While the thermal properties were sufficiently

well explained by the theories of Debye, it was necessary

to develop a theory of fracture mechanics in order to

explain mechanical properties. Whereas initially aluminium

oxide and later zirconium oxide, were first used as

ceramic construction materials, the outstanding properties

of covalently bonded materials based on silicon (silicon

carbide, silicon nitride, SIALONe etc.) were recognised

and exploited at the end of the 1960s. Research into

all these materials continues today. In addition to

the approaches of fracture mechanics, new mathematical

methods and computer simulations have been developed

in order to understand the relationship between microstructure

and properties through modelling. In parallel with the

theoretical developments, process technologies have

been optimised, extending as far as the introduction

of completely new process sequences and sintering methods.

Known materials continue to be improved,

new materials are being developed, and new applications

are being found. The materials of today can no longer

be compared with those that were on the market ten or

twenty years ago. Scientific research is increasing

our understanding of materials. New and improved manufacturing

technologies have brought progress in the areas of quality,

reproducibility and operating safety.

|

|