4.2.5 Ceramic

Coatings

Ceramic coatings, which offer the excellent

properties of ceramics such as high hardness and wear resistance,

electrical insulation, low thermal conductivity and reproducible

surface structures, are used for surface protection.

Thick film and thin film techniques are differentiated in

the manufacture of ceramic coatings.

Thick films (> 20 µm) are applied, for example, by

thermal spraying. Plasma spraying has shown excellent results

in this application. During plasma spraying, oxide ceramic

powder or powder mixtures such as aluminium oxide, aluminium

oxide / titanium dioxide, zirconium oxide and chromium oxide

are melted in a plasma flame at approx. 10,000 °C and

sprayed on a previously sandblasted metal surface.

Figure 73: The principle of plasma spraying

However, it is necessaryto ensure that before

plasma spraying a fissured surface is created through sandblasting

to which the ceramic particles can cling as they arrive.

Several layers are applied, so that a lamellar layer structure

with good adhesion results.

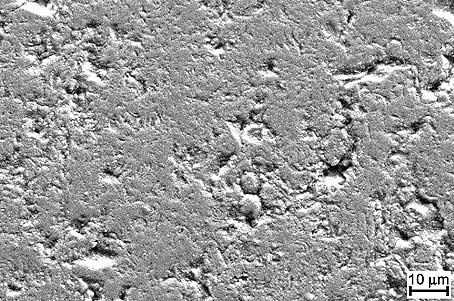

Figure 74: Section through a coating showing

the intermediate layer

Figure 75: Ground surface of a chromium oxide coating

An advantage of this process is that any metallic material

(with the exception of magnesium) can be coated with ceramics.

Oxide ceramic powders such as pure white aluminium oxide may

be applied for electrical insulation and as a protection against

wear, or zirconium oxide for thermal insulation. For increased

wear resistance, mixtures of aluminium oxide and titanium

dioxide in various proportions are used. Titanium dioxide

stabilises the alpha phase of aluminium oxide and makes this

ceramic coating tough, and resistant to impact and fracture.

Its colour varies between grey, blue grey and black, depending

on the mixture. Chromium oxide is preferred over metallic

materials for bearings and pumps because of its very good

tribological properties. An intermediate layer of nickel-chromium

(the ‘bond coat’) improves adhesion.

The ceramic surface is brought to a reproducible roughness

through subsequent machining. In most applications, a standard

surface with an Ra = 1.5 to 2 µm has been found to be

reliable. A shiny surface with a Ra  0.5 µm is achieved through hard machining.

0.5 µm is achieved through hard machining.

For aluminium oxide, the hardness of the ceramic layers is

around HV  1,800. In comparison, the hardness of hardened steel is around

HV

1,800. In comparison, the hardness of hardened steel is around

HV  700, and that of hard-chromed surfaces around HV

700, and that of hard-chromed surfaces around HV  1,200.

1,200.

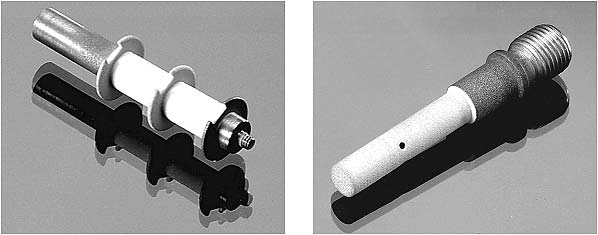

Figure 76: Components coated for wear resistance

The advantage of an insulation layer 0.1 to 0.5 mm thick is

the saving of space. It is, moreover, insensitive to heat,

shock, and, to a certain degree, to aggressive media and wear.

Due to the porous lamellar structure, stainless steel is recommended

as the substrate in corrosive environments. An important application

of ceramic coatings is their electrical insulation (up to

approximately 500 V) at operating temperatures over 200°

C, for example of heating elements. The ceramic layer adheres

reliably up to 600 °C.

The metal parts should be free from visible blow-holes, scratches

and pores, since the growth of the ceramic layer reproduces

any surface irregularities. A finely turned or polished metal

surface with Rz = 8 to 16 µm is recommended. The thickness

of the metal parts should be a minimum of 1 mm in order to

avoid heat build-up, which can deform the parts. Thin sheets

or wires cannot therefore be plasma sprayed. The maximum length

of the metal parts to be coated is dependent on the size of

the chamber and extract ducting available, and is typically

limited to 2 m.

Figures 77 and 78: Components with coatings

for electrical and thermal insulation

Adhesion to edges is limited. For this reason,

edges should be rounded to have a radius > 0.7 mm. Consideration

of the clamping region (thread or pin) is necessary if a design

appropriate for coating is to be achieved. Products can also

be partially coated. In this case, the metallic surfaces are

covered where necessary.

These coating procedures using ceramics are suitable for experimental

batches of 1 to 10 as well as for production series of 10,000

or more.

The procedure offers a facility for rapid production at short

notice. It allows metal parts to be created on CNC machines,

coated and further processed within a few days.

Repair coatings are also of interest. Used ceramic coatings

that have been damaged by shocks and impacts during heavy

use can simply be sandblasted away. Expensive metal parts

can be re-ground and coated with ceramic again.

Plasma sprayed coatings have proved themselves, for example,

in textile and wire drawing machines.

Thin films (< 20 µm) are applied by PVD (physical

vapour deposition) or CVD (chemical vapour deposition), by

galvanic processes or by sol-gel processes. Here, for example,

tools with the familiar gold coloured TiN coatings have found

wide acceptance.

|

|