3.4.1.3 Cordierite

Cordierite materials and

others based on it are magnesium aluminosilicates, fabricated

by sintering soapstone or talcum with the addition of clay,

kaolin, fireclay, corundum and mullite. A simplified approximation

to the composition of pure ceramic cordierite is approx. 14

% MgO, 35 % Al2O3 and 51 % SiO2.

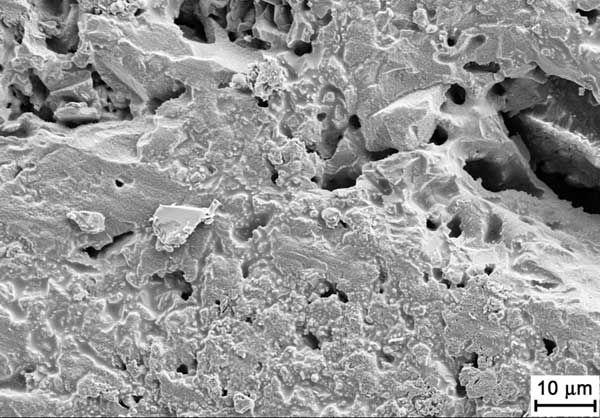

Figure 5: Microstructure of a porous cordierite

(C 520)

Cordierite materials have a low coefficient

of thermal expansion. This is the reason for their outstanding

thermal shock resistance combined with good mechanical strength.

Two types of cordierite, porous and dense, are distinguished.

The porous type has a low bending strength but even higher

thermal shock resistance than the dense type, since it can

absorb mechanical stresses in its porous structure.

Cordierite materials, moreover, behave inertly towards heating

element alloys at temperatures up to 1,000°C or even 1,200

°C (there is no reaction between the heating element and

the ceramic).

For this reason, cordierites are often found

in electric heating applications, and in heat engineering

in general.

Applications include, for example, insulators for continuous

flow electric water heaters, heating element pipes, heating

element supports in furnaces, link heaters, heating cartridges

for soldering irons, gas heater inserts, spark protectors

and catalyst carriers in automobiles.

For special purposes a material is available

containing cordierite and mullite and having a high aluminium

oxide content (C 530) which, for instance, permits higher

application temperatures.

|

|