3.4.2 Oxide Ceramics

3.4.2.1 Aluminium oxide

Aluminium oxide (Al2O3)

is the most important technical oxide ceramic material and

has the widest range of applications. Densely sintered aluminium

oxide is characterised by

These synthetically manufactured materials

with aluminium oxide contents ranging from 80 % to more than

99 %, have been proven in practice. The choice of this material

is determined by technical and economic criteria. A material

with higher aluminium oxide content does not necessarily fulfil

the needs of an application best.

It is also possible for the mechanical properties of aluminium

oxides from different manufacturers to vary, even when the

aluminium oxide content is the same, due to different powder

formulations.

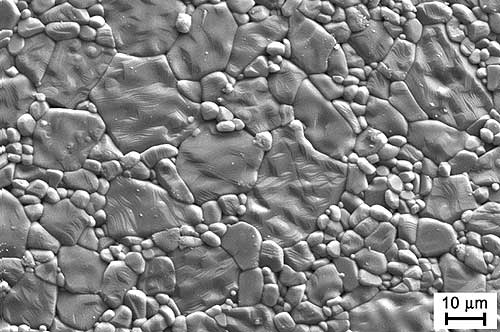

Figure 6: Surface of an

aluminium oxide "as fired"

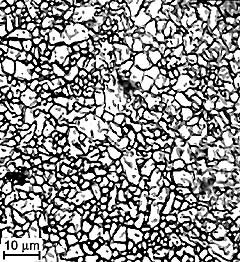

Figure 7: Microstructure of an aluminium

oxide ceramic (99.7 %)

Aluminium oxide materials satisfy all the

requirements of insulation materials for applications in electrical

engineering. Outstanding values for bending strength and for

resistance to wear and to high temperatures suit the material

to mechanical applications.

The microstructure, and therefore the other

properties, of aluminium oxide ceramics can differ markedly

(see Figures 8 and 9).

Figure 8:

Figure 8: Microstructure of a micro-crystalline

aluminium oxide |

Figure 9:

Figure 9: Microstructure of a coarse-crystal

aluminium oxid |

Surfaces with the highest possible bearing

area are not always either necessary or desirable. Thread

guides used in the textile industry, for instance, should

have a small contact area with the thread and should not have

any sharp edges, whereas sealing plates require a material

proportion of approx. 80 %.

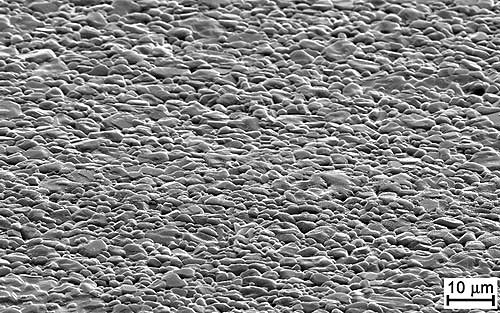

Figure 10: "As fired"

surface of a extruded aluminium oxide

Due to their good price/performance ratio and their generally

useful properties, aluminium oxide ceramics are used

- in the sanitary industry as a sealing

element,

- in electrical engineering as insulation,

- in electronics as a substrate,

- in machine and plant construction as

wear protection (wear-resistant material),

- in the chemical industry as corrosion

protection (corrosion-resistant material, highly resistant

to vapours, melting and slag up to high temperatures) and

as a filter,

- in instrumentation as a protective tube

for thermocouples used for high temperature measurements

- in human medicine as an implant, and

- in high temperature applications as

a burner nozzle or as a support tube for heat conductors.

|

|