The powder particles are compacted to form

a coherent shape with sufficient strength for subsequent handling.

If necessary, this shaped, unsintered mass of powder (known

as a green body) can be machined economically before firing,

since corresponding steps are much more expensive after sintering.

When applying the various forming processes, care must be

taken to avoid significant density gradients and textures

in the green body, since these can be amplified during sintering,

leading to distortions and internal mechanical stresses. The

choice of a suitable forming process is usually determined

by economic factors (efficient manufacturing).

Methods of shaping ceramic parts can be divided into the

following basic types:

is used to manufacture mass-produced precision products.

Non-clumping granulates are compressed in steel dies designed

appropriately for the part to be manufactured. The high cost

for the dies (sometimes made of carbide) can only usually

be justified for large runs.

Figure 53: Dry pressing

Figure 54: Single axis dry pressing, single

and double ended, with regions of different compression

(grey levels)

Dry pressing is the most economic process

for large production runs, and is suitable for both simple

and complex geometries. Depressions and holes are normally

only designed in the pressing direction.

Depending on the design of the dry pressing machine, components

ranging in size from tiles down to match heads can be manufactured.

Small discs or plates can be pressed with thicknesses of

around 0.8 or 1.0 mm. The tape casting process is more suitable

for even thinner, flatter components. It is still possible

to manufacture fine ridges or similar structures on the

component if the granulate being pressed can effectively

fill hollows in the pressing tool, and provided it is possible

to create the necessary tool.

Isostatic pressing

is suitable for the manufacture of uniformly

compressed blanks and large parts that are appropriate for

machining in the green state. Simple rubber moulds determine

the initial form.

Figure 55: Isostatic pressing with regions

of different compression (grey levels)

This type of forming is well-suited to the manufacture of

exacting prototypes and small series, but for some products

can also be fully automated (spark plugs, grinding balls,

small pistons, welding nozzles).

Wet pressing / moist pressing

allows the manufacture of parts with complex geometries

such as screw threads, side holes, recesses and undercuts.

The unfired material used for this purpose usually has moisture

levels in the range of 10 to 15%. Compressing with a single

axis makes these materials able to flow freely, so that

relatively even compression can be achieved.

The disadvantage of this, however, is that wet pressing

materials can accept only low compressive strains. This

also means that the degree of compression is limited. It

depends heavily on the moisture content of the unfired material,

and is lower than in the case of dry pressed parts. In some

circumstances, moreover, it is necessary to dry the pressed

parts before sintering. Mean tolerances in accordance with

DIN 40 680-1 are based on this.

Extrusion

is carried out using piston extruders or vacuum screw presses.

The homogenised mass of material is pressed through a nozzle,

so forming endless billets. Optimum compression of the material

is important. Extrusion is particularly suitable for manufacturing

rotationally symmetric parts such as axles or pipes. Complex

profiles can also be made with the aid of appropriate nozzle

design. The lengths of the billets to be manufactured depend

to a large extent on the tendency of the material being

processed to warp.

Figure 56: Extrusion

Injection moulding

is principally suited to the mass production of complex

products. It is limited by relatively high die costs and

the complex burnout of organic additives. The conveying

capacity ("shot weight") of large injection moulding

machines is typically up to about 70 g. Generally, the part

should be designed so that thicknesses are as consistent

as possible, having an upper limit of approx. 12 mm.

Slip casting

is a simple method for the manufacture of prototypes, parts

with complex geometries and relatively large items. It can

be used to manufacture both thin-walled and solid objects.

Ceramic slip casting involves a stable suspension, referred

to as the slip, being poured into a porous, absorbent plaster

mould. Extraction of the suspending liquid causes a layer

of particles to develop on the mould wall. This layer develops,

in solid casting, to create the fully moulded body. In the

case of hollow casting, the superfluous slip is poured out

once the desired wall thickness has been achieved.

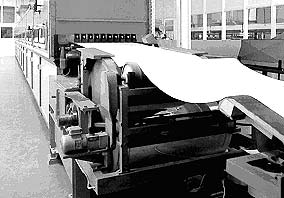

Tape casting

Here, a ceramic slip containing various organic additives

is poured onto an endless steel strip carried by rollers.

The slip flows continuously from a reservoir through an

adjustable slot onto the strip. Hot air is blown over the

strip in the opposite direction to dry it, so that at the

end of the strip, thanks to the organic additives, a flexible

tape of green ceramic is obtained. This can either be wound

up and stored for further processing at a later time, or

maybe processed immediately through cutting, punching, stamping

or other similar methods. Tape casting is typically used

to manufacture ceramic parts with thickness ranging from

0.25 to 1.0 mm. The formed products are suited for the manufacture

of substrates, housings, capacitors and multi-layer transducers.

Figure 57: Tape casting

Figure 58: Tape casting machine

The choice

of the forming process to be used in any particular case

depends, from a technical point of view, on the geometry

and size of the part and the needs of the application. The

piece count, raw material consumption and process costs

determine the most economic choice.

Further extensions to the forming processes initially introduced

here are possible.

Table 3: Summary of ceramic

forming processes

Table 4: Advantages and disadvantages of common

forming processes